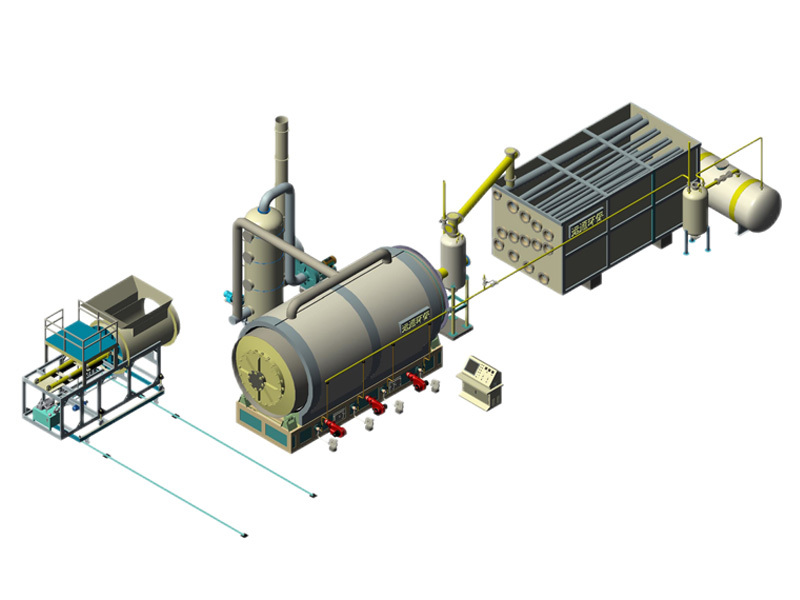

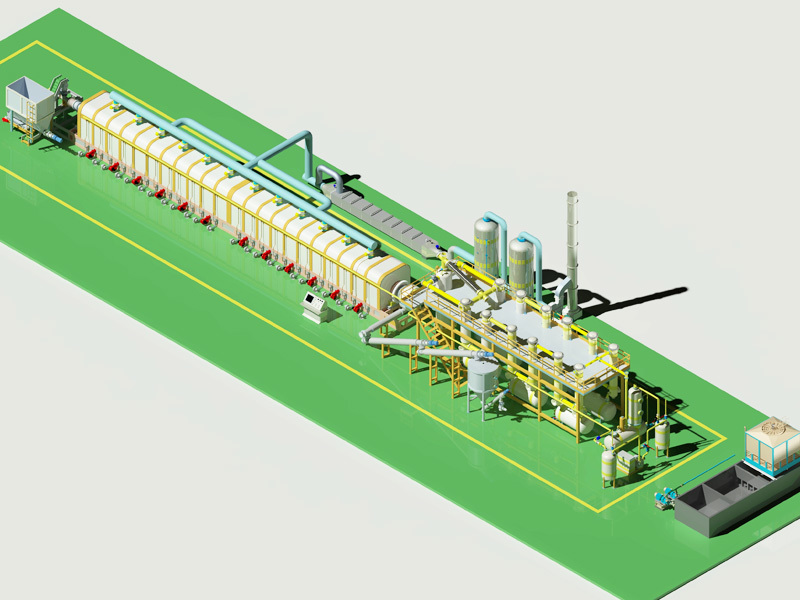

SQYT-9 series of equipments

Product Introduction

Product Advantages

SQYT-9 series of equipments, which adopt scientific airtight production and automation control process technology, are the advanced large-scaled industrial equipments domestic and international in the waste rubber products treatment fields. They work to recycle waste rubber into treasurable and valuable products again.

Throughout the production process, there is no secondary pollution generated. The generated combustible unliquefied gas will be compressed and collected into gas-storage tanks, to be sold or used for other purpose.

The equipments are of excellent configuration, higher automatic controlling, unique high efficiency heating system, making the equipments occupy international leading level.

Product Parameters

| ITEM | Batch Pyrolysis Plant | Continuous Pyrolysis Plant |

| Capacity | 10T,12T,15T per 24 hours | 10T,20T,30T ,40-50T,100T per 24 hours,28-30 days continuous working |

| Main reactor material | Q245R,Q345R,SS, | SS |

| Main reactor thickness | 16-20mm | 18mm |

| Toal weight | 30-40 T | 60-80T |

| Fuels | Oil,nature gas,electricity | Oil,nature gas,electricity |

| Power | 20-30KW | 50-150KW |

| Land required | 240-300M2 | 260-2000M2 |

| Labor required | 3 persons per batch | 2 persons per 24 hour |

Process Description:

a. Waste Materials are loaded into the pyrolysis chamber by the Feeding machine

b. System is started with the control panel operated by operator. The process is automatic and controlled by our control system. The first stage of the process is to heat up and dried up the waste.

c. Pyrolysis of the waste will begin once reaching a certain temperature and the sync gas is generated from the waste.

d. The sync gas will be converted into oil by the condensers and stored in the oil tank. Small quantity of sync gas which is not converted into oil is scrubbed by the scrubbing system and cleaned before released to air.

e. Upon completion of the pyrolysis process, chamber will be required to cool to a certain temperature before releasing the carbon black.

f. The carbon black will be released by our high speed carbon discharge system automatically and stored in a special tank which is to prevent pollution.

g. Steel (for tires contain steel wires) will be removed at the final stage upon the carbon black being fully released. Steel removal requires opening the big door.

h. The next batch of process can be continued.

key word:

Related Products

Related Products

Get A Quote

Leave your contact information and get a free product quote